Ever struggled with a rusty iron pipe that won’t budge during a plumbing project? You’re not alone. Cutting iron pipe properly separates DIY novices from skilled home handymen and professional plumbers. When your cast iron or black iron pipe needs cutting for repairs or modifications, using the wrong technique can lead to jagged edges, damaged threads, or even injury. This guide delivers exactly what you need to know about how to cut iron pipe safely and effectively, whether you’re replacing a section in your basement or installing new gas lines. You’ll discover the right tools for different pipe sizes, avoid common mistakes that waste time, and achieve clean cuts that make installation seamless.

Why Standard Pipe Cutters Fail on Iron Pipe

Iron pipe requires specialized cutting approaches because of its density and composition. Unlike copper or PVC, cast iron and black iron pipes resist standard pipe cutters designed for softer materials. Attempting to use a standard wheel cutter often results in slipping, uneven cuts, or complete tool failure. The high carbon content in cast iron makes it brittle yet tough to cut cleanly. Black iron pipe, commonly used for gas lines, has threaded ends that are easily damaged by improper cutting techniques. Understanding these material properties prevents wasted effort and ensures you select the right cutting method from the start.

How Iron Pipe Composition Affects Cutting Methods

Cast iron contains 2-4% carbon, making it hard but brittle. This composition means it chips rather than bends when cut improperly. Black iron pipe has lower carbon content but is still significantly harder than copper. The threaded ends on black iron pipe are particularly vulnerable—aggressive cutting techniques can damage these threads, requiring complete pipe replacement. When planning how to cut iron pipe, always consider whether you’re working with cast iron (typically in drainage systems) or black iron (common in gas lines), as each requires slightly different approaches.

Essential Safety Gear for Cutting Iron Pipe

Must-Have Protective Equipment Checklist

- Eye protection: Safety glasses with side shields or a full face shield (metal shards fly during cutting)

- Heavy-duty gloves: Leather work gloves to protect against sharp edges

- Respiratory protection: N95 mask when cutting cast iron (produces hazardous dust)

- Hearing protection: Especially when using power tools like angle grinders

- Fire-resistant clothing: Critical when cutting near gas lines or using torch methods

Skipping proper safety gear when cutting iron pipe leads to preventable injuries. The metal shards produced are razor-sharp, and cast iron dust contains silica that damages lungs. Always set up your work area away from flammable materials and ensure adequate ventilation.

6 Effective Methods to Cut Iron Pipe

Using a Hacksaw for Precision Control

The humble hacksaw remains one of the most reliable methods for cutting iron pipe, especially in tight spaces. For best results, use a fine-tooth blade (32 teeth per inch) specifically designed for metal cutting. Secure the pipe firmly in a vise with the cut line just above the jaws. Apply steady, moderate pressure while maintaining a consistent 45-degree angle. Rotate the pipe periodically to ensure an even cut. Though slower than power methods, this approach gives you complete control and minimizes damage to surrounding areas.

Pro Tip: Apply cutting oil to the blade teeth to reduce friction and extend blade life—this makes cutting through iron pipe significantly smoother.

Angle Grinder Cutting Technique

An angle grinder with a metal cutting disc delivers fast results for iron pipe cutting. Choose a 4.5-inch grinder with a thin metal-cutting wheel (0.045-inch thickness). Mark your cut line completely around the pipe with a permanent marker. Hold the grinder perpendicular to the pipe and start the cut at a single point. Work your way around slowly, applying light pressure. For larger diameter pipes, make multiple shallow passes rather than forcing a single deep cut.

Warning: Never force the grinder—let the disc do the work. Forcing causes binding, dangerous kickback, and ruined cuts.

Reciprocating Saw Method for Tight Spaces

When space constraints prevent using other tools, a reciprocating saw with a metal-cutting blade works surprisingly well for iron pipe. Use a bi-metal blade with 18-24 TPI (teeth per inch) and apply cutting fluid during operation. Clamp the pipe securely and start cutting at the lowest speed setting. Support the pipe on both sides of the cut to prevent blade binding as you complete the cut.

Time Saver: Wrap the pipe with masking tape along your cut line—this reduces blade wandering and creates a cleaner cut.

Pipe Wheel Cutter Adaptation for Black Iron

While standard pipe cutters struggle with iron, specialized heavy-duty cutters work for black iron pipe under 2 inches in diameter. Look for cutters rated specifically for cast iron with replaceable hardened steel wheels. Apply significant pressure on the initial scoring pass, then tighten the mechanism incrementally with each rotation. Lubricate the cutting wheel with pipe dope or specialized cutting fluid to reduce friction.

Critical Mistake to Avoid: Never attempt to cut cast iron drainage pipe with a wheel cutter—it will shatter unpredictably.

How to Cut Cast Iron Drain Pipe Without Creating a Mess

Cast iron drain pipes require special handling due to their brittleness and the hazardous dust they produce. Traditional cutting methods often cause cracking or create dangerous silica dust. The safest approach uses a specialized cast iron cutter with a scoring wheel and expansion mechanism that gradually fractures the pipe along a controlled line.

Step-by-Step Cast Iron Cutting Process

- Clean the pipe surface thoroughly where you’ll make the cut

- Measure and mark your cut line completely around the pipe

- Position the cast iron cutter and tighten until the wheel scores the surface

- Rotate the cutter around the pipe several times, tightening incrementally

- Continue tightening and rotating until the pipe separates cleanly

- Immediately clean up all pipe fragments and dust using a HEPA vacuum

Pro Tip: Place a plastic tarp underneath your work area to catch falling debris and simplify cleanup.

Deburring and Finishing Your Iron Pipe Cut

A clean cut is only half the battle—proper deburring ensures smooth installation and prevents leaks. After cutting iron pipe, use a pipe reamer or deburring tool to remove sharp edges from both the inside and outside of the pipe. For threaded black iron pipe, carefully chase the threads with a die to restore any damaged sections. Always wipe the pipe clean with a dry cloth to remove metal shavings before assembly.

Critical Quality Check Points

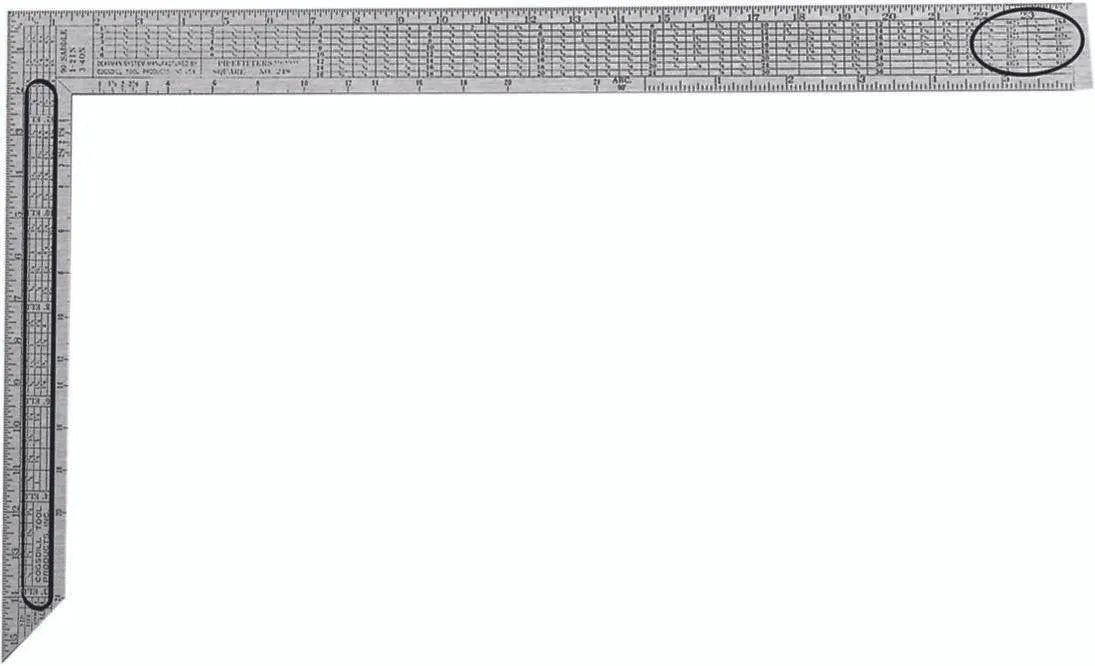

- Verify the cut is perpendicular to the pipe (use a square)

- Check for burrs by running your finger (carefully!) around the edge

- Inspect threads for damage if working with black iron

- Ensure no metal fragments remain inside the pipe

Preventing Common Iron Pipe Cutting Mistakes

The Alignment Error That Causes Leaks

The most frequent mistake when cutting iron pipe is creating an uneven cut. Even a slight angle prevents proper seating of fittings, guaranteeing leaks. Always use a pipe square or wrap a square piece of paper around the pipe to create a perfect perpendicular marking line. Double-check your alignment before starting any cut.

Thread Damage Prevention

When cutting threaded black iron pipe, protect existing threads by wrapping them with masking tape before cutting. Position your cut at least one inch from existing threads to allow for rethreading if necessary. Never use excessive force near threaded sections.

When to Call a Professional for Iron Pipe Cutting

Some situations warrant professional help rather than DIY attempts. Call a plumber if you’re working with gas lines under pressure, cutting large diameter cast iron pipes (over 4 inches), or dealing with pipes in extremely tight spaces. Gas line cutting requires special permits and leak testing in most jurisdictions—don’t risk dangerous gas leaks by attempting complex cuts without proper training and equipment.

Maintenance Tips to Extend Your Cutting Tools’ Life

Proper tool care saves money and ensures clean cuts every time. After cutting iron pipe, clean blades thoroughly to remove metal residue. Store cutting discs in their original packaging to prevent warping. Lubricate the moving parts of manual cutters regularly. Replace blades at the first sign of dullness—forcing a dull blade creates poor cuts and increases safety risks.

Final Note: Always measure twice and cut once when working with iron pipe. Keep replacement fittings on hand in case a cut goes wrong, and never rush the process—taking time to cut iron pipe properly prevents costly callbacks and repairs down the line. With these techniques mastered, you’ll handle iron pipe cutting projects with professional confidence.