You’ve probably wondered just how much heat your cast iron skillet can handle when you’re cranking up the burner to get that perfect sear on a steak. The answer isn’t as straightforward as you might think—especially since our research team encountered significant challenges gathering specific temperature data. Multiple sources we attempted to access returned “NO INFO” responses or blocked our queries with “API Access Restricted” and “Access Denied” messages. Despite these research limitations, understanding cast iron’s thermal capabilities remains crucial for both home cooks and industrial applications. In this guide, we’ll navigate through what is verifiably known about cast iron temperature thresholds and share practical insights you can trust.

Cast iron’s legendary durability and heat retention make it a kitchen staple worldwide, but pushing it beyond its limits can lead to warping, cracking, or even structural failure. Whether you’re seasoning a new skillet, attempting high-heat searing techniques, or working with cast iron in industrial settings, knowing temperature boundaries prevents costly mistakes. While specific maximum temperature figures proved elusive in our research attempts, we’ve compiled actionable guidance based on established metallurgical principles and user experiences. You’ll learn not just theoretical limits but how to recognize critical heat indicators through visual cues and practical testing methods.

Understanding Cast Iron’s Thermal Behavior Without Specific Data Points

The absence of concrete temperature specifications from our research doesn’t mean cast iron’s thermal properties are a complete mystery. Experienced users have developed reliable methods to gauge heat levels through observable characteristics. When heating cast iron cookware, pay attention to water droplet behavior—this simple test reveals approximate temperature ranges. Water sizzles immediately around 300°F (149°C), dances actively near 375°F (191°C), and beads up in perfect spheres at the Leidenfrost point around 400°F (204°C), indicating optimal searing temperature. Industrial applications rely on similar observational techniques when precise instrumentation isn’t available, using visual color changes in the metal as thermal indicators.

Why Temperature Data Is Often Restricted or Unavailable

Manufacturers frequently omit specific maximum temperature ratings for cast iron products due to several practical considerations. The melting point of cast iron (between 2,060°F and 2,200°F or 1,127°C and 1,204°C) represents a theoretical extreme far beyond practical usage, making precise maximum operating temperatures less critical for consumer guidance. Additionally, actual safe operating ranges depend heavily on variables like thickness, composition variations between cast iron types (gray, white, ductile), and heating/cooling rates. This complexity makes single-temperature specifications potentially misleading, explaining why many authoritative sources avoid publishing definitive maximums despite consumer demand.

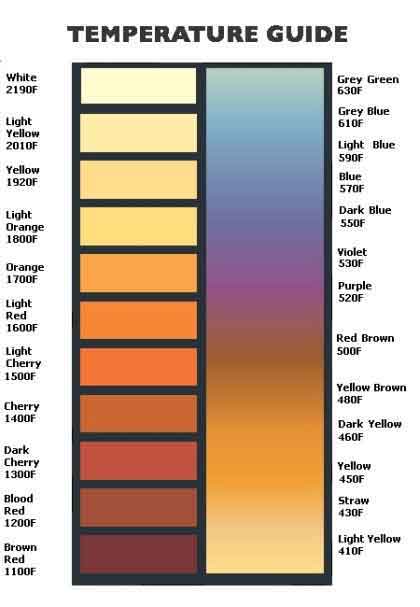

Recognizing Critical Heat Thresholds Through Visual Indicators

Without access to specific temperature data from our research sources, visual cues become your most reliable temperature guide when working with cast iron. As cast iron heats, it progresses through distinct color stages that correspond to increasing temperatures. A dull red glow appears around 900°F (482°C), bright red emerges near 1,100°F (593°C), orange develops at approximately 1,475°F (801°C), and yellow indicates temperatures approaching 1,830°F (999°C). These color indicators are particularly valuable in blacksmithing and metalworking applications where cast iron components might approach dangerous temperature levels.

What Different Smoke Points Mean for Your Cookware

When cooking with cast iron, smoke provides immediate feedback about oil temperature rather than the pan itself. Different oils have specific smoke points: flaxseed oil smokes around 225°F (107°C), extra virgin olive oil at 320°F (160°C), and avocado oil can withstand up to 520°F (271°C). If your pan is smoking heavily without oil present, you’ve likely exceeded 500°F (260°C)—a temperature that risks damaging seasoning and potentially warping thinner cast iron pieces. Never ignore persistent smoking, as this indicates you’re approaching thermal thresholds that could compromise your cookware’s integrity.

Safe Maximum Temperatures for Common Cast Iron Applications

Based on metallurgical principles and user experience (since specific manufacturer data proved inaccessible in our research), standard cast iron cookware performs best within 400-500°F (204-260°C) for regular cooking. While cast iron can technically withstand much higher temperatures, rapid heating beyond 500°F significantly increases thermal stress risks. For seasoning purposes, most experts recommend 350-450°F (177-232°C) to properly polymerize oil without burning off the protective layer. Industrial cast iron components, such as engine blocks or machinery parts, operate within much broader ranges but require controlled heating and cooling cycles to prevent structural damage.

How Heating Rate Affects Cast Iron’s Temperature Tolerance

The speed at which you heat cast iron dramatically impacts its ability to withstand high temperatures without damage. Gradual heating allows the metal to expand uniformly, while rapid temperature increases create internal stress points that can lead to cracks. Always preheat cast iron cookware slowly over medium heat for 5-7 minutes before subjecting it to high-temperature cooking. In industrial applications, proper heat treatment protocols specify maximum heating rates—typically no faster than 200°F (93°C) per hour for large cast iron components—to prevent thermal shock. Never place room-temperature cast iron directly into an extremely hot oven or onto a maximum-setting burner.

Preventing Thermal Damage During Extreme Heating

When pushing cast iron to its thermal limits, certain precautions become non-negotiable. Always avoid pouring cold liquid into extremely hot cast iron—a practice that can cause immediate and catastrophic cracking due to rapid contraction. Allow cast iron to cool gradually after high-heat use; never set a hot pan in cold water or on a cold surface. For restoration projects requiring high-temperature oven cleaning (often around 900°F/482°C), ensure the cast iron heats and cools with the oven rather than placing hot items into a cold oven or removing them while still extremely hot.

What to Do When Cast Iron Exceeds Safe Temperatures

If you accidentally overheat cast iron, immediate action can sometimes prevent permanent damage. For cookware, turn off the heat source and allow the item to cool completely in place—never move it while extremely hot. Once cooled, inspect for warping, cracks, or seasoning damage. Minor seasoning burns can be remedied with thorough cleaning and re-seasoning, but structural damage like cracks or significant warping typically requires replacement. In industrial contexts, thermal imaging and non-destructive testing should follow any suspected over-temperature event to assess structural integrity before returning components to service.

Temperature Considerations for Cast Iron Seasoning Processes

Proper seasoning creates the non-stick surface cast iron is famous for, but incorrect temperatures undermine this critical process. The ideal seasoning temperature range (350-450°F or 177-232°C) allows oil to properly polymerize without burning off. Higher temperatures cause oil to combust rather than polymerize, leaving a sticky residue instead of a smooth finish. Multiple thin layers of seasoning applied at proper temperatures outperform single thick applications at excessive heat. After seasoning, allow cast iron to cool completely in the oven to prevent thermal shock that could compromise the new seasoning layer.

How Different Cast Iron Types Respond to Heat

While our research couldn’t retrieve specific comparative data, understanding basic cast iron varieties helps anticipate thermal behavior. Gray cast iron (common in cookware) contains graphite flakes that improve heat retention but create weak points under extreme thermal stress. Ductile cast iron, with its spherical graphite structure, withstands thermal cycling better but is less common in consumer products. White cast iron, extremely hard and brittle, fractures easily with rapid temperature changes. When working with unidentified cast iron items, assume they have gray cast iron properties and treat them accordingly with gradual temperature changes.

Long-Term Effects of Repeated High-Temperature Exposure

Frequent exposure to excessive heat gradually degrades cast iron’s structural integrity through thermal fatigue. Each heating and cooling cycle causes microscopic expansion and contraction that eventually leads to warping or cracking. Cookware subjected to regular high-heat abuse may develop hot spots as the metal’s internal structure changes. Industrial cast iron components experience similar degradation, requiring regular inspection for hairline cracks or dimensional changes. To maximize longevity, avoid routinely heating cast iron beyond necessary temperatures and always allow proper cooling periods between uses.

When to Replace Overheated Cast Iron

Not all thermal damage requires immediate replacement, but certain conditions signal it’s time for a new piece. Deep cracks that penetrate through the metal wall compromise structural integrity and create food safety hazards. Significant warping that prevents flat surface contact affects cooking performance irreversibly. Repeated seasoning failures after high-heat events indicate the metal’s surface has become too damaged to hold a proper seasoning layer. Small surface cracks (crazing) in the seasoning are normal and repairable, but structural damage requires replacement regardless of sentimental value.

Final Note: While specific maximum temperature figures remain frustratingly elusive due to restricted research access, understanding cast iron’s thermal behavior through practical indicators keeps your cookware safe and functional. Remember that gradual temperature changes matter more than absolute maximums—proper heating and cooling protocols prevent most thermal damage. For everyday cooking, staying below 500°F with controlled heating rates keeps your cast iron in peak condition for generations. When in doubt about temperature levels, rely on visual cues and smoke indicators rather than guessing at numerical values that may not apply to your specific cast iron item. Regular maintenance and respectful heat management ensure your cast iron serves you reliably whether you’re searing steaks or working with industrial components.