Nothing beats the satisfaction of transforming a rust-covered, neglected cast iron skillet into a gleaming, functional kitchen treasure. Many home cooks inherit or discover old cast iron pieces that appear beyond saving—coated in decades of rust, carbon buildup, or mystery residue. The good news is that with the right techniques, almost any cast iron cookware can be resurrected. Learning how to clean old cast iron cookware properly unlocks a world of durable, versatile cooking tools that can last generations. This guide gives you the exact steps to restore even the most neglected pieces to cooking-ready condition.

Assess Your Cast Iron Before Cleaning

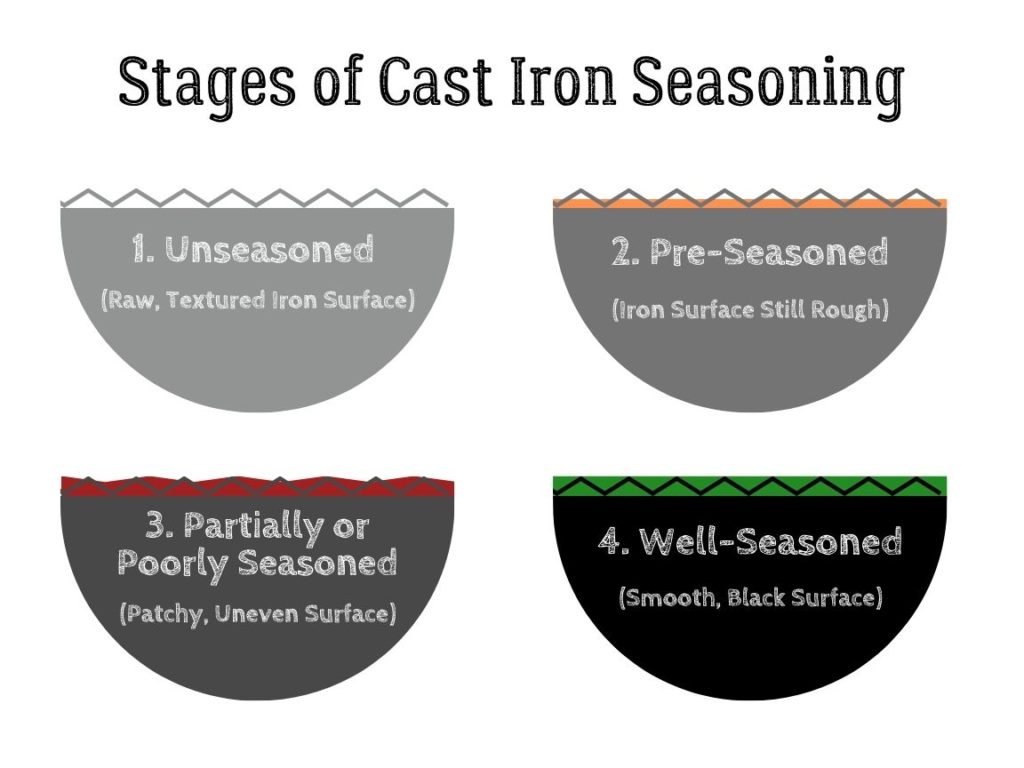

Before grabbing cleaning supplies, carefully evaluate your piece to determine the best restoration approach. Hold it under good lighting and examine every surface for cracks, chips, or warping in the metal. Structural damage that goes through the cooking surface makes the piece unsafe for use, though minor surface imperfections can often be worked around. Run your fingers across the cooking surface to gauge the rust situation—light surface rust feels slightly rough while heavy rust appears flaky and orange. Check for remnants of old seasoning, which should be smooth and dark black when in good condition. Some vintage pieces may have chemical coatings from the mid-20th century that need complete removal before proper seasoning can take hold.

Essential Safety Precautions

Restoring old cast iron demands proper safety measures to protect both you and the cookware. Wear nitrile or rubber gloves throughout the process, especially when handling cleaning solutions or scrubbing abrasive materials. Rust particles and cleaning agents can irritate skin, and old cast iron often has sharp edges. Work in well-ventilated areas when using vinegar, chemical strippers, or electrolysis methods—these processes release fumes that shouldn’t be inhaled. Support heavy pieces properly during cleaning; cast iron becomes incredibly slippery when wet and can cause serious injury if dropped. Keep eye protection nearby for when you’re aggressively scrubbing rust or using mechanical removal methods.

Remove Loose Debris and Surface Residue

Start your restoration with basic cleaning to eliminate loose particles that could interfere with deeper cleaning. Use a stiff-bristled brush or wire grill brush to dislodge decades of accumulated dust, food residue, and loose rust. Work over a trash can or outdoors to contain the mess. For stubborn baked-on carbon, gently scrape with a metal spatula or putty knife, being careful not to gouge the metal surface. Once loose material is removed, wash the piece with warm water and a small amount of mild dish soap using a non-abrasive sponge. This preliminary wash removes surface oils and grease without damaging any remaining good seasoning. Rinse thoroughly and dry immediately with a clean towel to prevent flash rust.

Deep Cleaning Methods for Stubborn Buildup

When basic washing doesn’t cut through years of grime, employ these targeted deep cleaning techniques based on your piece’s condition.

Vinegar Soak for Heavy Rust Removal

For cast iron with significant rust, create a 50/50 solution of white vinegar and water in a plastic container large enough to submerge your piece completely. Soak for 8-24 hours, checking periodically—the vinegar will turn dark as it dissolves rust. Don’t exceed 24 hours as prolonged exposure can damage the metal. After soaking, scrub with a brass-bristled brush to remove loosened residue, then rinse thoroughly. This method works because vinegar’s acetic acid breaks down iron oxide without harming the underlying cast iron.

Baking Soda Paste for Carbon Buildup

Make a thick paste of baking soda and water to tackle stubborn food residue and light surface rust. Apply generously to affected areas and let sit for 15-20 minutes before scrubbing with a soft brush. The mild abrasiveness lifts residue without scratching the metal. For particularly tough spots, bring the paste to a simmer in the pan with a small amount of water, then scrub while warm. Baking soda’s alkaline properties help break down acidic carbon deposits that have baked onto the surface over years of use.

Neutralize Acid and Prevent Flash Rust

After using vinegar or other acid-based methods, neutralizing is critical to stop ongoing corrosion. Rinse your cast iron thoroughly in a solution of one-quarter cup baking soda per gallon of water. This alkaline solution counteracts any residual acid that would otherwise continue eating away at the metal. Follow with a final rinse in clean water to remove all traces of the neutralizing solution. Dry immediately using clean, lint-free towels—water left on bare cast iron causes flash rust within minutes. For complete drying, place the piece in a 200-250°F oven for 10-15 minutes to evaporate moisture from microscopic pores in the metal.

Strip Remaining Seasoning If Necessary

Degraded, sticky, or uneven seasoning often requires complete removal before proper restoration. The oven self-cleaning method effectively strips old seasoning by burning off organic material at 900°F or higher. Place your cast iron in a cold oven, run the self-clean cycle, and wait for complete cooling before removal—this produces significant smoke, so ensure excellent ventilation. For chemical stripping, use caustic soda-based products according to manufacturer directions, then neutralize with vinegar and rinse thoroughly. Mechanical stripping with sandpaper or wire wheels gives precise control but requires elbow grease—start with 100-grit sandpaper and progress to 400-grit for a smooth finish.

Apply Fresh Seasoning Layers

Proper seasoning creates the non-stick surface that makes cast iron invaluable. Choose an oil with a high smoke point like grapeseed, canola, or flaxseed oil—apply a microscopic amount to all surfaces using a clean cloth, then wipe until the metal looks completely dry. Excess oil leads to sticky, uneven seasoning. Place the oiled cookware upside down in a preheated 450-500°F oven for one hour, then turn off the heat and allow to cool completely inside. Repeat this process 3-5 times for optimal results. The key is thin, even layers—multiple applications build a durable, polymerized coating that improves with each use.

Maintain Your Restored Cast Iron

Proper maintenance keeps your restored piece in excellent condition with minimal effort. Clean immediately after cooking while the pan is still warm using hot water and a stiff brush—avoid harsh detergents that strip seasoning over time. For stuck-on food, add a small amount of water to the warm pan and bring to a simmer before scrubbing. Dry completely with a towel, then place on a warm burner for a minute to evaporate any remaining moisture. Apply a drop of oil to the cooking surface after drying and buff it in for added protection. Store in a dry location with air circulation, placing paper towels between stacked pieces to prevent seasoning damage.

Avoid Common Cast Iron Cleaning Mistakes

Even well-intentioned cooks make errors that damage their cast iron. Never soak cast iron for extended periods—water causes rust and damages seasoning. Avoid harsh abrasives like steel wool on seasoned surfaces; save these for restoration projects only. Skipping thorough drying is the most common mistake—always dry completely immediately after washing. Using excessive oil when cooking creates sticky residue and uneven heating; proper seasoning requires only a light coating of oil. Remember that properly maintained cast iron improves with age—the seasoning layer builds up over time, becoming increasingly non-stick and resilient.

Restore Heirloom Pieces with Patience

Vintage cast iron often carries both monetary and sentimental value. Research your piece’s history before restoration—brands like Griswold, Wagner, and early Lodge have collector appeal. Preserve original characteristics like heat rings or smooth cooking surfaces that contribute to both functionality and value. Document your restoration process with photos to track progress and share with fellow enthusiasts. For exceptionally valuable pieces, consider consulting a professional restoration specialist before proceeding. The time invested in careful restoration pays dividends each time you use your revitalized cookware, connecting you to centuries of culinary tradition while creating new memories in your kitchen.

With these techniques, you’ve gained the knowledge to clean old cast iron cookware and maintain it for generations to come. That rust-covered skillet you thought was trash can become your most reliable kitchen companion, developing its own unique patina through years of use. The initial effort transforms neglected metal into functional art that improves with every meal prepared—a true kitchen heirloom ready to pass along to future cooks.